In oil and gas production, many types of direct and indirect fired heaters are used. Starting and operating a gas or oil-burning heater can pose a serious risk to any facility's operation. Installing a burner management system (BMS) on the process boiler is one approach to mitigate the risk. The BMS is an engineered hazard control used by oil and gas operators to ensure that a process heater is safely started, operated, and shut down. It also helps reduce fuel and maintenance costs, improve uptime, and create safe atmosphere for workers working near the heater. In an upset circumstance, a burner management system also prevents process heaters from exploding.

Burner management systems are widely used in various industries to improve plant operations by assuring reliable and safe burner operations, lowering maintenance costs, improving safety, and providing a safer work environment for all oil and gas plants operators. The BMS system must be correctly designed and work well throughout the equipment's lifecycle to protect people and the plant. Thus, the factors mentioned above are driving the US oil and gas burner management system market growth.

Workers in the oil & gas industry are at risk of fire and explosion if explosive Vapours or gases are ignited. Wells, trucks, production equipment, and surface equipment such as tanks and shale shakers can all produce flammable gases such as well gases, Vapours, and hydrogen sulphide. Static, electrical energy sources, open flames, lightning, cigarettes, cutting and welding instruments, hot surfaces, and frictional heat are all examples of ignition sources. Attention to personnel safety is paramount in industrial manufacturing facilities' design, construction, operation, and maintenance. Catastrophic equipment failure can result from years of seemingly innocuous negligence or inadequate operation and maintenance, resulting in serious and fatal damage. There is probably no more potentially dangerous equipment running in an industrial production facility than steam and power generating equipment due to possible catastrophic failure induced by inadequate operation and maintenance methods. If not managed and maintained properly, the boiler is often the largest, most expensive, and perhaps most dangerous piece of equipment.

The performance of the burner management system and the performance of the plant are linked. Although a poorly designed system that is prone to erroneous trips, light-off issues, and difficult troubleshooting may still protect plant equipment and employees. Further, these trips' process interruptions can significantly impact plant operability and performance. A BMS is a vital component of combustion safety. The BMS monitors the process for harmful situations while regulating the combustion unit's safe light-off, start up, and shutdown. The system must be correctly designed and work well throughout the equipment's lifecycle to protect people and the plant. The system should incorporate best practices in selecting and maintaining field equipment, utilizing safety-rated equipment, collecting and analysing essential BMS data, and employing a sequenced approach to logic design to reduce lost production as operations and maintenance troubleshoot BMS problems. Best practices in BMS guarantee that safety conditions are identified and accounted for, allowing operators to identify upset sources rapidly and reliably. As a result of increased investment in safety, the oil and gas burner management system market is growing.

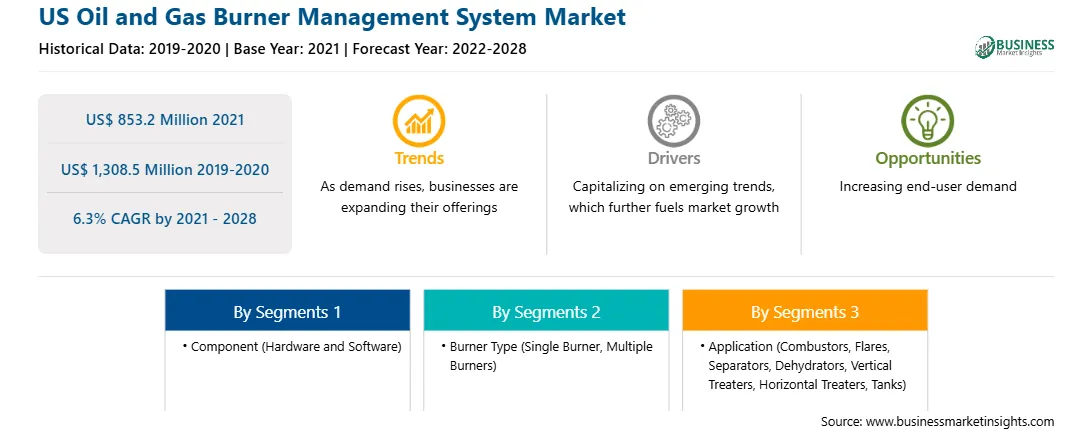

Based on burner type, the US oil and gas burner management system market is segmented into single burner and multiple burners. The burner management system are engineered to provide igniter (pilot) and main flame detection. They also control and monitor burner start-up and shutdown sequences, including master fuel trip and purge, for both multiple and single burners, which can burn single or multiple liquid and gaseous fuels. In the oil & gas industry, the BMS is critical to use on heated vessels where precise temperature control is needed.

Based on application, the US oil and gas burner management system market is segmented into combustors, flares, separators, dehydrators, vertical treaters, horizontal treaters, tanks, and others. BMS systems help improve overall plant performance, reduce possession charges, and ensure plant control adherence. They stop the equipment from starting and firing up until the combustion chamber purge is completed, control the sequencing of components during start-up and shut-down of the system, protect against the admission of inappropriate quantities of fuel to the heater, and provide status and feedback on component condition to the operator. Whether the application may be an industrial furnace, dryer, fluid bed incinerator, steam boiler, or other combustion equipment, companies are providing burner management systems to various applications.

The players operating in the US oil and gas burner management system market adopt strategies such as mergers, acquisitions, and market initiatives to maintain their positions in the market. A few developments by key US oil and gas burner management system market players are listed below:

The global US oil and gas burner management system market is segmented on the basis of component, burner type, and application. Based on component, the market is segmented into software and hardware. In terms of burner type, the US oil and gas burner management system market is segmented into single burner and multiple burner. By application, the market is segmented into combustors, flares, separators, dehydrators, vertical treaters, horizontal treaters, tanks, and others.

ACL Manufacturing Inc., Cimarron Energy, Combustex Corp., Kimark Control Solutions, Platinum Control Technologies, and profire Energy Inc are among the key US oil and gas burner management system market players considered for the research study. In addition, several other significant market players have been studied and analyzed in the research report to get a holistic view of the market and its ecosystem.

Strategic insights for the US Oil and Gas Burner Management System provides data-driven analysis of the industry landscape, including current trends, key players, and regional nuances. These insights offer actionable recommendations, enabling readers to differentiate themselves from competitors by identifying untapped segments or developing unique value propositions. Leveraging data analytics, these insights help industry players anticipate the market shifts, whether investors, manufacturers, or other stakeholders. A future-oriented perspective is essential, helping stakeholders anticipate market shifts and position themselves for long-term success in this dynamic region. Ultimately, effective strategic insights empower readers to make informed decisions that drive profitability and achieve their business objectives within the market.

| Report Attribute | Details |

|---|---|

| Market size in 2021 | US$ 853.2 Million |

| Market Size by 2028 | US$ 1,308.5 Million |

| Global CAGR (2021 - 2028) | 6.3% |

| Historical Data | 2019-2020 |

| Forecast period | 2022-2028 |

| Segments Covered |

By Component

|

| Regions and Countries Covered | United States

|

| Market leaders and key company profiles |

The geographic scope of the US Oil and Gas Burner Management System refers to the specific areas in which a business operates and competes. Understanding local distinctions, such as diverse consumer preferences (e.g., demand for specific plug types or battery backup durations), varying economic conditions, and regulatory environments, is crucial for tailoring strategies to specific markets. Businesses can expand their reach by identifying underserved areas or adapting their offerings to meet local demands. A clear market focus allows for more effective resource allocation, targeted marketing campaigns, and better positioning against local competitors, ultimately driving growth in those targeted areas.

The US Oil and Gas Burner Management System Market is valued at US$ 853.2 Million in 2021, it is projected to reach US$ 1,308.5 Million by 2028.

As per our report US Oil and Gas Burner Management System Market, the market size is valued at US$ 853.2 Million in 2021, projecting it to reach US$ 1,308.5 Million by 2028. This translates to a CAGR of approximately 6.3% during the forecast period.

The US Oil and Gas Burner Management System Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the US Oil and Gas Burner Management System Market report:

The US Oil and Gas Burner Management System Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The US Oil and Gas Burner Management System Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the US Oil and Gas Burner Management System Market value chain can benefit from the information contained in a comprehensive market report.