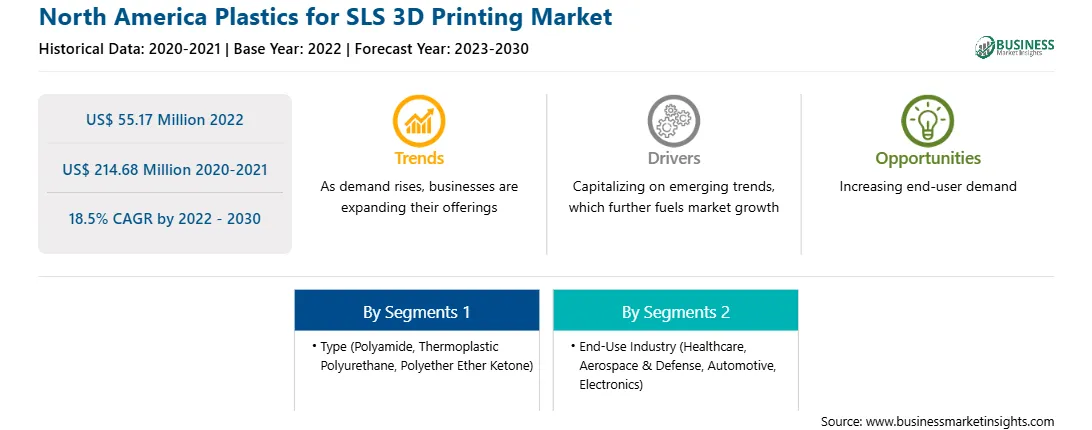

The North America plastics for SLS 3D printing market was valued at US$ 55.17 million in 2022 and is expected to reach US$ 214.68 million by 2030; it is estimated to grow at a CAGR of 18.5% from 2022 to 2030.

Many companies are focused on the continuous development of SLS-compatible plastic materials with improved properties, such as durability, heat resistance, and flexibility. For instance, companies such as HP and BASF have been collaborating to develop innovative SLS materials. They have introduced PA11 and PA12 nylon materials that exhibit not only improved strength but also increased flexibility, making them suitable for applications ranging from automotive components to consumer goods. These materials are designed to withstand extreme conditions while maintaining their integrity. Moreover, advancements in heat-resistant plastics are becoming increasingly relevant, especially in the aerospace and industrial sectors. Advanced materials, such as ULTEM, are known for their exceptional heat resistance and flame-retardant properties. These materials have found applications in producing aircraft interiors and components for critical machinery operating in high-temperature environments. In the healthcare sector, the development of biocompatible plastic materials for SLS has enabled the creation of patient-specific implants and surgical tools. These materials not only exhibit high strength and flexibility but also meet stringent biocompatibility standards. Therefore, rising awareness regarding the development of SLS-compatible plastic materials is propelling their use in different application sectors such as automotive, aerospace & defense, and healthcare, thereby driving the North America plastic for SLS 3D printing market.

SLS 3D printing is increasingly adopted in a wide range of industries, such as aerospace, automotive, healthcare, and manufacturing. This is due to the advantages of SLS 3D printing over conventional manufacturing methods, such as the ability to produce complex and customized parts with high precision and accuracy. SLS 3D printing is well-suited for prototyping and rapid manufacturing applications because SLS 3D printers can produce high-quality parts in a relatively short amount of time. SLS 3D printing is also employed for rapid prototyping and manufacturing of medical devices, surgical equipment, diagnostic tools, prosthetics, and implants. The presence of SLS 3D printing companies in the region is further expected to boost the demand for plastics for SLS 3D printing. SLS 3D printing companies are strategizing business expansion to cater to the rising demand from end-use industries. For instance, in 2023, Nexa3D announced the acquisition of XYZ Printing's SLS printing operations.

The growth of automotive and aerospace industries in the region is further anticipated to create lucrative opportunities for plastics for the SLS 3D printing market. As per the International Organization of Motor Vehicle Manufacturers, in 2022, North America registered a production of 14.79 million vehicles. As per a report by the American Automotive Policy Council, car sales in the region are expected to exceed 17.7 million vehicles per year by 2025. North America marks the presence of several aerospace companies, such as Precision Castparts Corp, Spirit AeroSystems, Textron, General Dynamics, L3Harris Technologies, and GE Aviation. According to a report by the International Trade Administration (ITA), the government of Canada allocated US$ 1.36 billion through the Federal Strategic Innovation Fund to support the aerospace sector in 2021-2022. Canada ranks among the top 5 aerospace goods export markets for the US, and it exported 56.6% of goods required in US-based industries manufacturing aircraft, engines, and components in 2021. SLS 3D printing is used for manufacturing varied aerospace components, including jet engines, fixtures, brackets, turbine blades, ducting systems, heat exchangers, and fuel nozzles. Therefore, the growth of automotive and aerospace industries in the region is expected to drive the demand for plastics for SLS 3D printing.

Strategic insights for the North America Plastics for SLS 3D Printing provides data-driven analysis of the industry landscape, including current trends, key players, and regional nuances. These insights offer actionable recommendations, enabling readers to differentiate themselves from competitors by identifying untapped segments or developing unique value propositions. Leveraging data analytics, these insights help industry players anticipate the market shifts, whether investors, manufacturers, or other stakeholders. A future-oriented perspective is essential, helping stakeholders anticipate market shifts and position themselves for long-term success in this dynamic region. Ultimately, effective strategic insights empower readers to make informed decisions that drive profitability and achieve their business objectives within the market.

| Report Attribute | Details |

|---|---|

| Market size in 2022 | US$ 55.17 Million |

| Market Size by 2030 | US$ 214.68 Million |

| Global CAGR (2022 - 2030) | 18.5% |

| Historical Data | 2020-2021 |

| Forecast period | 2023-2030 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

The geographic scope of the North America Plastics for SLS 3D Printing refers to the specific areas in which a business operates and competes. Understanding local distinctions, such as diverse consumer preferences (e.g., demand for specific plug types or battery backup durations), varying economic conditions, and regulatory environments, is crucial for tailoring strategies to specific markets. Businesses can expand their reach by identifying underserved areas or adapting their offerings to meet local demands. A clear market focus allows for more effective resource allocation, targeted marketing campaigns, and better positioning against local competitors, ultimately driving growth in those targeted areas.

The North America plastics for SLS 3D printing market is segmented based on type, end-use industry, and country.

Based on type, the North America plastics for SLS 3D printing market is categorized into polyamide, thermoplastic polyurethane (TPU), polyether ether ketone (PEEK), and others. The polyamide segment held the largest North America plastics for SLS 3D printing market share in 2022.

In terms of end-use industry, the North America plastics for SLS 3D printing market is segmented into healthcare, aerospace & defense, automotive, electronics, and others. The electronics segment held the largest North America plastics for SLS 3D printing market share in 2022.

Based on country, the North America plastics for SLS 3D printing market is segmented into the US, Canada, and Mexico. The US dominated the North America plastics for SLS 3D printing market in 2022.

3D Systems Corp, BASF SE, Evonik Industries AG, Arkema SA, Ensinger GmbH, Stratasys Ltd, Sinterit Sp Zoo, EOS GmbH, and CRP Service SRL are some of the leading companies operating in the North America plastics for SLS 3D printing market.

1. 3D Systems Corp

2. BASF SE

3. Evonik Industries AG

4. Arkema SA

5. Ensinger GmbH

6. Stratasys Ltd

7. Sinterit Sp Zoo

8. EOS GmbH

9. CRP Service SRL

The North America Plastics for SLS 3D Printing Market is valued at US$ 55.17 Million in 2022, it is projected to reach US$ 214.68 Million by 2030.

As per our report North America Plastics for SLS 3D Printing Market, the market size is valued at US$ 55.17 Million in 2022, projecting it to reach US$ 214.68 Million by 2030. This translates to a CAGR of approximately 18.5% during the forecast period.

The North America Plastics for SLS 3D Printing Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the North America Plastics for SLS 3D Printing Market report:

The North America Plastics for SLS 3D Printing Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The North America Plastics for SLS 3D Printing Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the North America Plastics for SLS 3D Printing Market value chain can benefit from the information contained in a comprehensive market report.