In-mold-electronics (IME) is a ground-breaking way of integrating electronics into the plastics. This technology offers immense possibilities for electronics manufactures and product designers to create 3D contoured smart electronic surfaces. IME facilitates the production of lightweight, ergonomic, and durable parts by cost-effective manufacturing processes necessitating less assembly and fewer moving parts. In-mold-electronics combines in-mold decorating (IMD) technology with the printed electronics. Major benefits obtained by using this technology include overall system cost reductions, superior design flexibility, and improved manufacturing productivity. Designers seeks for the technology as it facilitates them to eliminate the buttons and multiple layers that are involved in the assembly of conventional electro-mechanical switches and to replace them with pre-integrated plastic parts. In-mold electronics are significantly gaining popularity in the automotive, white goods, and medical device markets across North America for the creation of smart surfaces within their products. Moreover, in the near future, several other North American markets are expected to adopt this technology as the consumer interests and technology advantages are recognized. North America is a crucial market for the future growth of in-mold electronics market over the forecast period. The US and Canada are the key countries witnessing high growth in various manufacturing industries. This aspect will fuel the demand for in-mold electronics technology which will drive the North America in-mold electronics market growth. Factors such as development in capacitive touch sensors and several benefits of in-mold electronics such as less time, space, cost etc. is expected to drive the North America in-mold electronics market growth.

Moreover, in case of COVID-19, North America region especially the U.S. witnessed an unprecedented rise in number of confirmed cases resulting in large-scale lockdown across different regions as well as industrial activities. As a result, several small & medium enterprise owners have limited their industry personnel whereas many other have laid off non-essential employees shortly owing to restricted business operation. In addition to this, the company also minimized the allocated budget for manufacturing of electronics owing to economic slowdown, which affected the global nosiness activities which has also affected the North America in-mold electronics market. Moreover, the component manufacturer, supply chain and distributor lack of availability of business also has significantly influencing the production of electronics by the market players. Thus, the North America in-mold electronics market is expected to witness a major drop in the demand from the end-users for the current year and the subsequent years to recover from the impact of COVID-19 pandemic

Strategic insights for the North America In-Mold Electronics provides data-driven analysis of the industry landscape, including current trends, key players, and regional nuances. These insights offer actionable recommendations, enabling readers to differentiate themselves from competitors by identifying untapped segments or developing unique value propositions. Leveraging data analytics, these insights help industry players anticipate the market shifts, whether investors, manufacturers, or other stakeholders. A future-oriented perspective is essential, helping stakeholders anticipate market shifts and position themselves for long-term success in this dynamic region. Ultimately, effective strategic insights empower readers to make informed decisions that drive profitability and achieve their business objectives within the market.

| Report Attribute | Details |

|---|---|

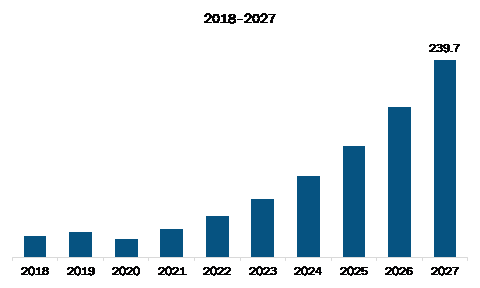

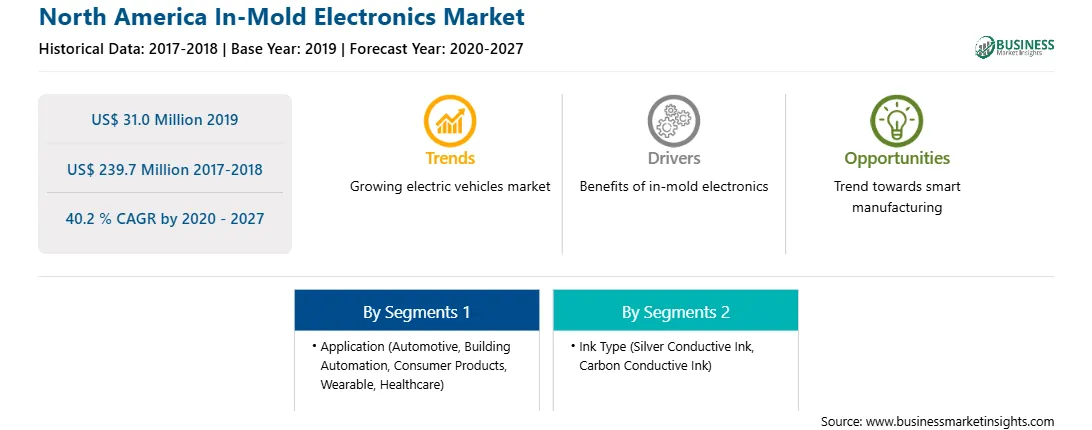

| Market size in 2019 | US$ 31.0 Million |

| Market Size by 2027 | US$ 239.7 Million |

| Global CAGR (2020 - 2027) | 40.2 % |

| Historical Data | 2017-2018 |

| Forecast period | 2020-2027 |

| Segments Covered |

By Application

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

The geographic scope of the North America In-Mold Electronics refers to the specific areas in which a business operates and competes. Understanding local distinctions, such as diverse consumer preferences (e.g., demand for specific plug types or battery backup durations), varying economic conditions, and regulatory environments, is crucial for tailoring strategies to specific markets. Businesses can expand their reach by identifying underserved areas or adapting their offerings to meet local demands. A clear market focus allows for more effective resource allocation, targeted marketing campaigns, and better positioning against local competitors, ultimately driving growth in those targeted areas.

The North America in-mold electronics market is expected to grow from US$ 31.0 million in 2019 to US$ 239.7 million by 2027; it is estimated to grow at a CAGR of 40.2 % from 2020 to 2027. Perforation of in-mold electronics in various industries is expected to escalate the North America in-mold electronics market growth. It is expected that the North America market for in-mold-electronics will show significant growth beginning in the 2023 to 2024 period. The movement will start with simple small-area devices and then progressing on to more complex, larger-area applications. In time, volumes will increase, with a particular emphasis on stringent reliability. Auto consoles and consumer appliances are the top products suitable for in-mold electronic-based touch panels at present. Many other industries across North America are studying in-mold technology to understand it better, seeing what they can do with it. At present, the technology leaders in North America are now charging ahead and getting production-ready for bringing out in-mold technology-based electronic components. So the advantages of in-mold electronics such as less costing, less space, light weight etc. are expected to increase its demand from various industries, which will drive the North America in-mold electronics market growth.

In terms of application, the automotive segment accounted for the largest share of the North America in-mold electronics market in 2019. In terms of ink type, the silver conductive Ink segment held a larger market share of the North America in-mold electronics market in 2019.

A few major primary and secondary sources referred to for preparing this report on the North America in-mold electronics market are company websites, annual reports, financial reports, national government documents, and statistical database, among others. Major companies listed in the report are Butler Technologies, Inc.; DuPont de Nemours, Inc.; DuraTech Industries; Eastprint Incorporated; Golden Valley Products; InMold Solutions; Nissha Co., Ltd.; TactoTek Oy.

The List of Companies - North America In-Mold Electronics Market

The North America In-Mold Electronics Market is valued at US$ 31.0 Million in 2019, it is projected to reach US$ 239.7 Million by 2027.

As per our report North America In-Mold Electronics Market, the market size is valued at US$ 31.0 Million in 2019, projecting it to reach US$ 239.7 Million by 2027. This translates to a CAGR of approximately 40.2 % during the forecast period.

The North America In-Mold Electronics Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the North America In-Mold Electronics Market report:

The North America In-Mold Electronics Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The North America In-Mold Electronics Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the North America In-Mold Electronics Market value chain can benefit from the information contained in a comprehensive market report.