Growing adoption of Industry 4.0 principles

Industry 4.0 fully automates production processes with minimal to negligible human intervention. It works on the industrial internet of things (IIoT), cyber-physical systems, cloud robotics, cloud computing, and big data. As a result, welding robot manufacturers are moving to produce networked and intelligent robots compatible with Industry 4.0. Many end-use industries, such as automotive and transportation, metals and machinery, electrical and electronics, and aerospace and defense, have begun to implement Industry 4.0 concepts in their manufacturing processes to harness the advantages associated with it, including increased productivity, flexibility, and safety, better quality, decreased need for consumables, and reduced production costs. Smart factories are a key feature of Industry 4.0. A smart factory adopts a so-called calm system. A calm system can manage both the physical world and the virtual. Such systems are called background systems and work somewhat behind the scenes. A calm system is aware of its surrounding environment and the objects around it. It can also be provided with soft information related to generated objects, such as drawings and models. Smart Factory containing hundreds or even thousands of smart devices capable of self-optimizing production will result in virtually zero downtime in production. This is leading to significant growth of the robotic welding cell market.

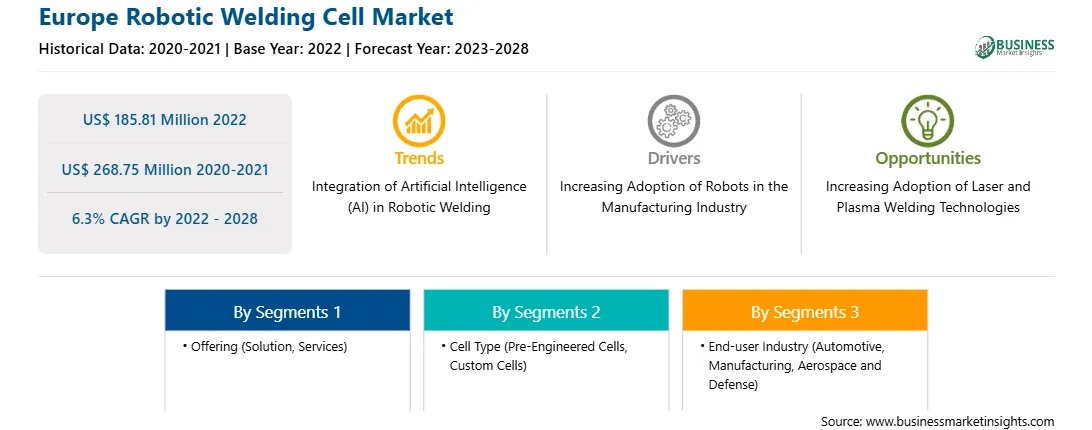

Market Overview

The Europe robotic welding cell market is segmented into Germany, France, Russia, the UK, Italy, and the rest of Europe. Europe is known for its large-scale industrialization and urbanization. Europe started from a strong position in robotics, holding 32% of the global market. Industrial robotics accounts for about one-third of the global market, while in the smaller professional robotic welding cell market, European manufacturers produce 63% of the non-military robots. Europe is a leader in the robotic welding cell market for field robotics, logistics, and construction. The use of robotics in this market is varied and used in professional cleaning. The military application of robotics is high in the professional use of service robotics. In defense, both manned and unmanned types of robots are used. In unmanned use, drones are very common. The use of drones increased in the battlegrounds over a few years. They are being used for intelligence, surveillance, and reconnaissance missions and help the soldiers on the battlefield and sitting far away to plan their next course of action.

Strategic insights for the Europe Robotic Welding Cell provides data-driven analysis of the industry landscape, including current trends, key players, and regional nuances. These insights offer actionable recommendations, enabling readers to differentiate themselves from competitors by identifying untapped segments or developing unique value propositions. Leveraging data analytics, these insights help industry players anticipate the market shifts, whether investors, manufacturers, or other stakeholders. A future-oriented perspective is essential, helping stakeholders anticipate market shifts and position themselves for long-term success in this dynamic region. Ultimately, effective strategic insights empower readers to make informed decisions that drive profitability and achieve their business objectives within the market. The geographic scope of the Europe Robotic Welding Cell refers to the specific areas in which a business operates and competes. Understanding local distinctions, such as diverse consumer preferences (e.g., demand for specific plug types or battery backup durations), varying economic conditions, and regulatory environments, is crucial for tailoring strategies to specific markets. Businesses can expand their reach by identifying underserved areas or adapting their offerings to meet local demands. A clear market focus allows for more effective resource allocation, targeted marketing campaigns, and better positioning against local competitors, ultimately driving growth in those targeted areas.

Europe Robotic Welding Cell Strategic Insights

Europe Robotic Welding Cell Report Scope

Report Attribute

Details

Market size in 2022

US$ 185.81 Million

Market Size by 2028

US$ 268.75 Million

Global CAGR (2022 - 2028)

6.3%

Historical Data

2020-2021

Forecast period

2023-2028

Segments Covered

By Offering

By Cell Type

By End-user Industry

Regions and Countries Covered

Europe

Market leaders and key company profiles

Europe Robotic Welding Cell Regional Insights

Europe Robotic welding Cell Market Segmentation

The Europe robotic welding cell market is segmented into offering, cell type, end user, and country.

Based on offering, the market is segmented into solution and services. The solution segment registered the largest market share in 2022. Based on cell type, the market is categorized into pre-engineered cells and custom cells. The pre-engineering segment held the largest market share in 2022. Based on end user, the Europe robotic welding cell market is segmented into automotive, manufacturing, and aerospace and defense. The manufacturing segment held the largest market share in 2022. Based on country, the market is segmented into Germany, France, Italy, the UK, Russia, and Rest of Europe. Rest of Europe dominated the market share in 2022. ABB Ltd; The Lincoln Electric Company; Kuka AG; Kawasaki Heavy Industries, Ltd.; Zeman Bauelemente Produktionsgesellschaft mbH; Carl Cloos Schweisstechnik GmbH and WEC Group Ltd are the leading companies operating in the robotic welding cell market in the region.

The Europe Robotic Welding Cell Market is valued at US$ 185.81 Million in 2022, it is projected to reach US$ 268.75 Million by 2028.

As per our report Europe Robotic Welding Cell Market, the market size is valued at US$ 185.81 Million in 2022, projecting it to reach US$ 268.75 Million by 2028. This translates to a CAGR of approximately 6.3% during the forecast period.

The Europe Robotic Welding Cell Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the Europe Robotic Welding Cell Market report:

The Europe Robotic Welding Cell Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The Europe Robotic Welding Cell Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the Europe Robotic Welding Cell Market value chain can benefit from the information contained in a comprehensive market report.