Industry 4.0 is revolutionizing the way companies make, improve, and sell their products. Aerospace, defense, transportation, and many industries implement latest technologies, including Internet of Things (IoT), cloud computing and analytics, artificial intelligence (AI), and machine learning (ML), to improve processes and overall operations. The industries adopt these technologies to automate time-consuming processes, use AI to make informed decisions, and use cloud services to streamline data management. Companies in the oil & gas industry are significantly adopting technologies, such as IoT and advanced analytics, to enhance operational efficiencies, cut costs, and optimize manual processes. The oil and gas companies experience several unplanned incidences such as pipe leakage, energy grid failure among others which cost millions to the company. Predictive maintenance enables these companies to rely on Industrial Internet of Things (IIoT)-enabled technologies, such as sensor data, and use predictive analytics for real-time equipment inspections, which helps reduce maintenance costs and unplanned equipment downtime. Further, the use of UAVs, such as drones, has significantly disrupted the oil & gas industry by removing the need for manual inspections of the pipelines in difficult-to-access locations. The UAVs are beneficial in dangerous situations, such as gas leaks, and support early detection through instant data collection and transfer. Hence, the benefits associated with using predictive analytics and UAVs boost the predictive maintenance market. In the manufacturing industry, manufacturers had to rely on a reactive maintenance model to repair only after a failure of unit, which caused high cost of maintenance and paralyzed long periods of unscheduled downtime. Hence, these factors inevitably led to a lower quality output produced. With predictive maintenance models integrated into IoT and IIoT, the manufacturing industry players can significantly reduce costs by eliminating the need for unnecessarily frequent maintenance. Hence, manufacturing companies are comprehensively integrating predictive maintenance models to identify and predict potential problems given the specific information extracted from each unit, thereby maintaining overall manufacturing health in the process. As a result, the rising prevalence of industry 4.0 coupled with the growing manufacturing units across the world drives the growth of the predictive maintenance market.

Europe is segmented into Germany, France, Italy, the UK, Russia, and rest of Europe. The predictive maintenance is cheaper and integrating more powerful sensors, and big data analytics offer an unprecedented opportunity to track machine-tool performance and health conditions. However, as per the European Commission, manufacturers only spend 15% of their total maintenance costs on predictive (vs reactive or preventative) maintenance, which is expected to hold the potential opportunity for the growth of predictive maintenance across various industries in Europe. The digital transformation in Europe enables to leverage the advanced digital technologies such as IoT, AI, Big Data, and others to drive efficiencies and thereby open up new opportunities for the same, which involve digital twins that evidently improve the efficiency of predictive maintenance of the critical assets and thereby mitigating the exposure of hazardous environment to the workers in the facilities. Europe's oil & gas industry is leading the energy sectors added with an increased focus on enhancing efficiencies and reducing downtime, aiding the need for predictive maintenance. Predictive maintenance uses data, such as temperature, vibration, and throughput, collected by sensors, then analyzed for any red flags or abnormal results. The growing adoption of advanced technology for predictive maintenance is improving the facility's operational efficiency, which is augmenting the demand for predictive maintenance propelling the market growth over the forecast period. For instance, in June 2021, Dietsmann Smart Labs established a strategic partnership with Norwegian Data Analytics specialist Arundo for breakthrough development with an integrated predictive maintenance software solution for an industrial plant.

Strategic insights for the Europe Predictive Maintenance provides data-driven analysis of the industry landscape, including current trends, key players, and regional nuances. These insights offer actionable recommendations, enabling readers to differentiate themselves from competitors by identifying untapped segments or developing unique value propositions. Leveraging data analytics, these insights help industry players anticipate the market shifts, whether investors, manufacturers, or other stakeholders. A future-oriented perspective is essential, helping stakeholders anticipate market shifts and position themselves for long-term success in this dynamic region. Ultimately, effective strategic insights empower readers to make informed decisions that drive profitability and achieve their business objectives within the market.

| Report Attribute | Details |

|---|---|

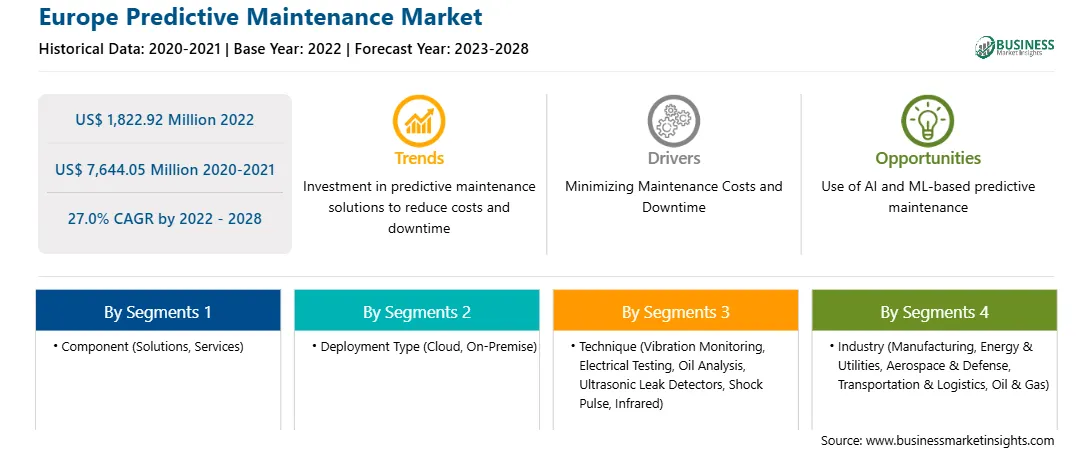

| Market size in 2022 | US$ 1,822.92 Million |

| Market Size by 2028 | US$ 7,644.05 Million |

| Global CAGR (2022 - 2028) | 27.0% |

| Historical Data | 2020-2021 |

| Forecast period | 2023-2028 |

| Segments Covered |

By Component

|

| Regions and Countries Covered | Europe

|

| Market leaders and key company profiles |

The geographic scope of the Europe Predictive Maintenance refers to the specific areas in which a business operates and competes. Understanding local distinctions, such as diverse consumer preferences (e.g., demand for specific plug types or battery backup durations), varying economic conditions, and regulatory environments, is crucial for tailoring strategies to specific markets. Businesses can expand their reach by identifying underserved areas or adapting their offerings to meet local demands. A clear market focus allows for more effective resource allocation, targeted marketing campaigns, and better positioning against local competitors, ultimately driving growth in those targeted areas.

The Europe predictive maintenance market is segmented based on component, deployment type, technique, industry, and country.

General Electric Company; Hitachi, Ltd.; IBM Corporation; Microsoft Corporation; PTC Inc.; SAS Institute, Inc.; Schneider Electric SE; Software AG; and Syncron AB are the leading companies operating in the Europe predictive maintenance market.

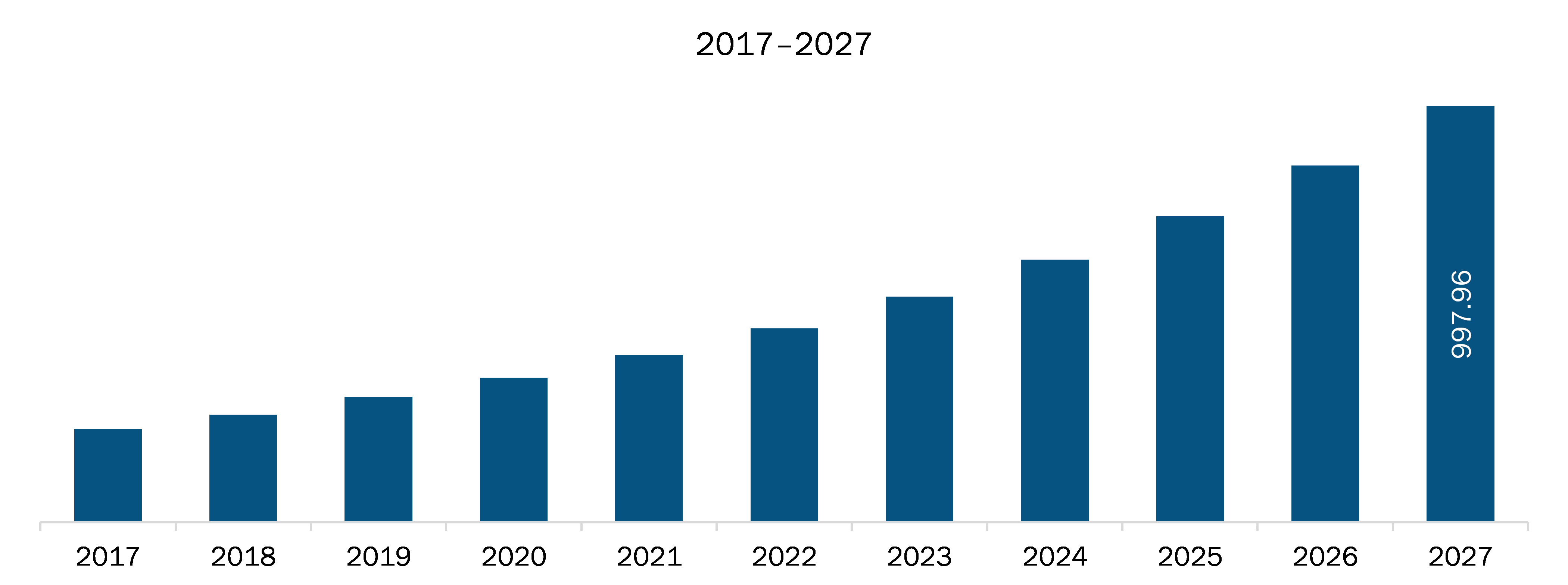

The Europe Predictive Maintenance Market is valued at US$ 1,822.92 Million in 2022, it is projected to reach US$ 7,644.05 Million by 2028.

As per our report Europe Predictive Maintenance Market, the market size is valued at US$ 1,822.92 Million in 2022, projecting it to reach US$ 7,644.05 Million by 2028. This translates to a CAGR of approximately 27.0% during the forecast period.

The Europe Predictive Maintenance Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the Europe Predictive Maintenance Market report:

The Europe Predictive Maintenance Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The Europe Predictive Maintenance Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the Europe Predictive Maintenance Market value chain can benefit from the information contained in a comprehensive market report.