Several governments worldwide have enacted strict automotive emission and fuel economy legislation standards. These standards aim to improve the overall efficiency of vehicles and reduce their carbon footprint. In order to meet the standards in limited time companies are adopting automation in their production lines. Owing to this, the number of active industrial robots worldwide is increasing by ~14% year on year, and automation is creating new types of robots with increased utility and function. Future factories will certainly have machines and humans working side by side to meet consumer demand—a new reality for which business owners should be prepared. This leads to increased production and less human fatigue and reduce overtime hours. Industry 4.0 refers to the present industrial revolution, driven by advancements in robotics, automation, and the Internet of Things (IoT). The growth of industrial IoT and artificial intelligence is likely to significantly impact robots. New maintenance tactics, more autonomous robots, and new collaborative robotics technologies are made possible by Industry 4.0 technology. Industrial robots and Industry 4.0 technologies can help revolutionize companies over the next few years by streamlining machine management and automating operations that were previously done by human hands. Companies are becoming more upfront about using industrial robots to automate and become a part of the global supply chain. Automation solutions enable remote digital connectivity and robot monitoring. The Asia Pacific industrial robotics market is growing from past decade due to the rise in global automation and the acceptance of industry 4.0 work models.

The Asia Pacific industrial robotics market is segmented into Australia, China, India, Japan, South Korea, and the Rest of Asia Pacific. Asia has the world's largest industrial robot market due to the region's high demand for industrial robots. The installation of industrial robots increased by 33% in 2021 compared to 2022. In 2021, the adoption of industrial robots in the electronics industry increased by 22%, the automotive industry by 57%, and the metal & machinery industry by 29%, compared to 2020. According to IFR, in January 2023, China, Japan, and South Korea were among the top five most advanced countries in terms of annual installations of industrial robots. In addition, governments of various countries in Asia Pacific are coming up with plans and initiatives to boost the Asia Pacific industrial robotics market growth. For instance, in December 2021, China unveiled a sharpened version of the Made in China 2025 industrial policy blueprint. Under this, the government released a five-year smart manufacturing development plan to digitize 70% of the country's large enterprises. In addition, New Robot Strategy by the Japanese government through investments in the manufacturing, healthcare, infrastructure, and agriculture sectors to integrate automated solutions further fueling the adoption of automated solutions. Such initiatives by the government will further boost the Asia Pacific industrial robotics market in the region. Market players operating in the Asia Pacific industrial robotics market in Asia Pacific include Mitsubishi Electric Corporation, Omron Corporation, and Hitachi Ltd. These companies engage in various organic and inorganic growth strategies to fuel their business growth. For instance, in April 2021, Hitachi Ltd acquired Kyoto Robotics, an intelligent robotics solution provider, due to the increasing need for automation during the pandemic.

Strategic insights for the Asia Pacific Industrial Robotics provides data-driven analysis of the industry landscape, including current trends, key players, and regional nuances. These insights offer actionable recommendations, enabling readers to differentiate themselves from competitors by identifying untapped segments or developing unique value propositions. Leveraging data analytics, these insights help industry players anticipate the market shifts, whether investors, manufacturers, or other stakeholders. A future-oriented perspective is essential, helping stakeholders anticipate market shifts and position themselves for long-term success in this dynamic region. Ultimately, effective strategic insights empower readers to make informed decisions that drive profitability and achieve their business objectives within the market. The geographic scope of the Asia Pacific Industrial Robotics refers to the specific areas in which a business operates and competes. Understanding local distinctions, such as diverse consumer preferences (e.g., demand for specific plug types or battery backup durations), varying economic conditions, and regulatory environments, is crucial for tailoring strategies to specific markets. Businesses can expand their reach by identifying underserved areas or adapting their offerings to meet local demands. A clear market focus allows for more effective resource allocation, targeted marketing campaigns, and better positioning against local competitors, ultimately driving growth in those targeted areas.

Asia Pacific Industrial Robotics Strategic Insights

Asia Pacific Industrial Robotics Report Scope

Report Attribute

Details

Market size in 2022

US$ 7,373.30 Million

Market Size by 2030

US$ 14,209.70 Million

Global CAGR (2022 - 2030)

8.5%

Historical Data

2020-2021

Forecast period

2023-2030

Segments Covered

By Types

By Function

By Industry

Regions and Countries Covered

Asia-Pacific

Market leaders and key company profiles

Asia Pacific Industrial Robotics Regional Insights

Asia Pacific Industrial Robotics Market Segmentation

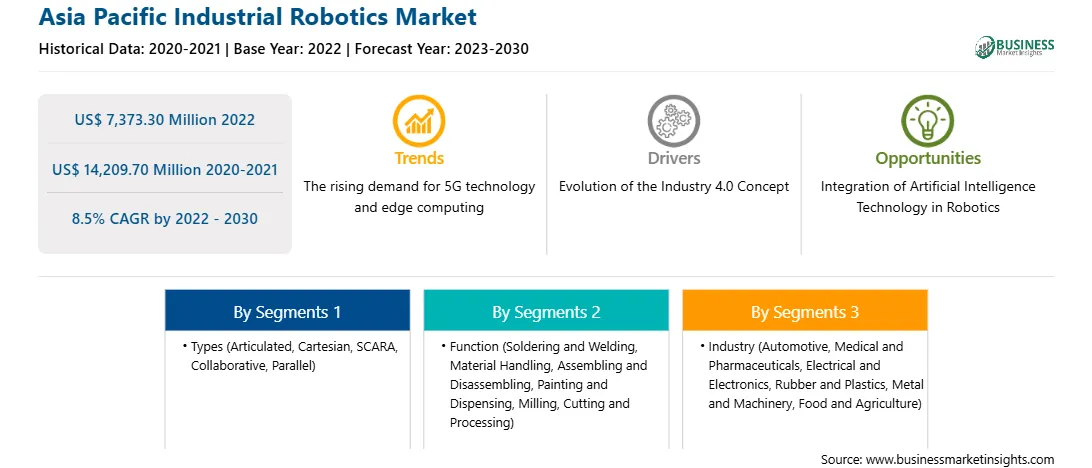

The Asia Pacific industrial robotics market is segmented into types, function, industry, and country.

Based on types, the Asia Pacific industrial robotics market is segmented into articulated, cartesian, SCARA, collaborative, parallel, and others. In 2022, the articulated segment registered the largest share in the Asia Pacific industrial robotics market.

Based on function, the Asia Pacific industrial robotics market is segmented into soldering and welding, material handling, assembling and disassembling, painting and dispensing, milling, and cutting and processing. In 2022, the soldering and welding segment registered the largest share in the Asia Pacific industrial robotics market.

Based on industry, the Asia Pacific industrial robotics market is segmented into automotive, medical and pharmaceuticals, electrical and electronics, rubber and plastics, metal and machinery, and food and agriculture. In 2022, the automotive segment registered the largest share in the Asia Pacific industrial robotics market.

Based on country, the Asia Pacific industrial robotics market is segmented into Australia, China, India, Japan, South Korea, Indonesia, Singapore, Malaysia, Taiwan, and the Rest of Asia Pacific. In 2022, China registered the largest share in the Asia Pacific industrial robotics market.

ABB Ltd, Comau SpA, Fanuc Corp, Kawasaki Heavy Industries Ltd, Kuka AG, Mitsubishi Electric Corp, Seiko Epson Corp, Staubli International AG, Universal Robots AS, and Yaskawa Electric Corp are some of the leading companies operating in the Asia Pacific industrial robotics market.

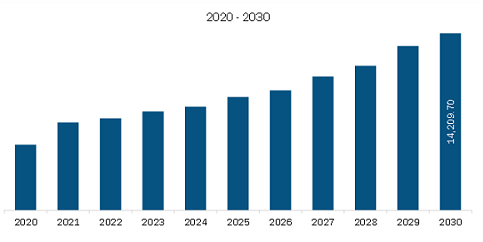

The Asia Pacific Industrial Robotics Market is valued at US$ 7,373.30 Million in 2022, it is projected to reach US$ 14,209.70 Million by 2030.

As per our report Asia Pacific Industrial Robotics Market, the market size is valued at US$ 7,373.30 Million in 2022, projecting it to reach US$ 14,209.70 Million by 2030. This translates to a CAGR of approximately 8.5% during the forecast period.

The Asia Pacific Industrial Robotics Market report typically cover these key segments-

The historic period, base year, and forecast period can vary slightly depending on the specific market research report. However, for the Asia Pacific Industrial Robotics Market report:

The Asia Pacific Industrial Robotics Market is populated by several key players, each contributing to its growth and innovation. Some of the major players include:

The Asia Pacific Industrial Robotics Market report is valuable for diverse stakeholders, including:

Essentially, anyone involved in or considering involvement in the Asia Pacific Industrial Robotics Market value chain can benefit from the information contained in a comprehensive market report.